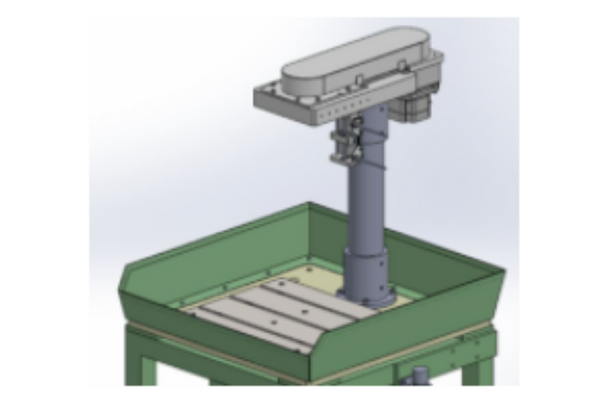

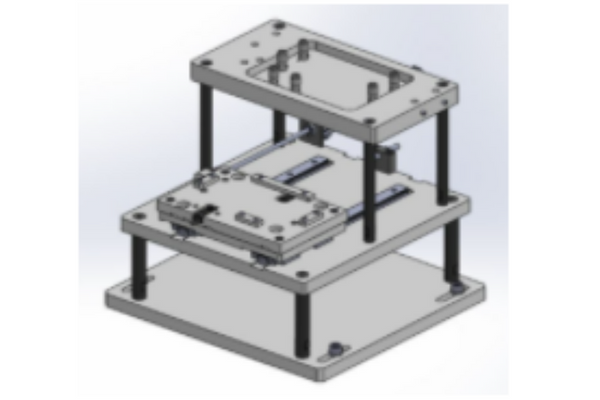

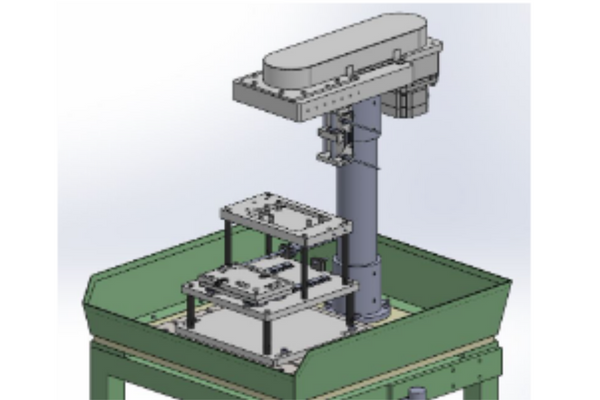

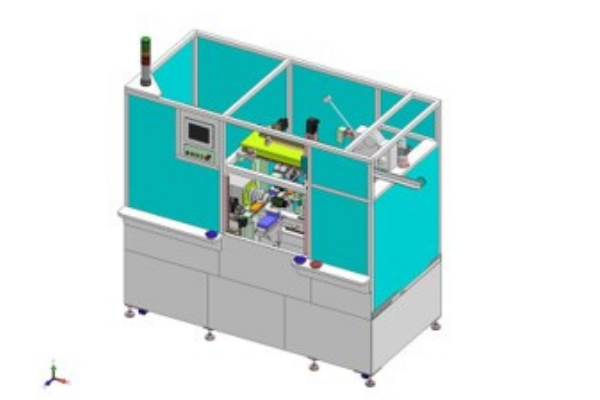

Tapping Machine

Description

A PLC is used for the control section, which enables changes in tool rotation speed, counter settings, etc.

The use of a touch panel allows the contents and layout of the operation to be changed, making the machine highly versatile.

This machine is mainly used for tapping after punching. This process is highly regarded in the industry where people use these types of machines.

Features

■Tool rotation speed can be changed, counters can be set, etc.

■Ability to change the content and layout of the operation.

■Multiple workpieces can be handled by changing the jig.

■Possible to process not only one side but also both sides at the same time.

What more EXCERA can do

-

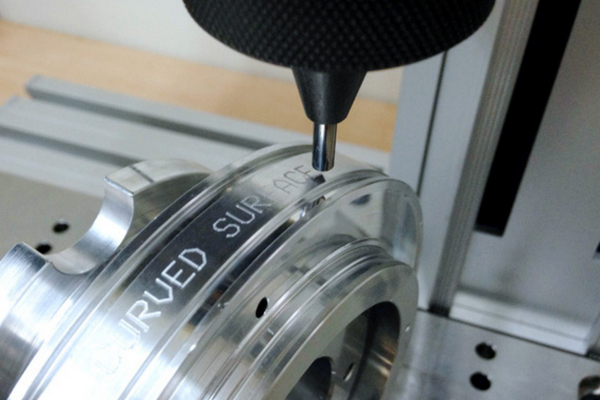

Engraving by Micro-Impact Engraving Machine

-

Semi-Automated Painting Machine

-

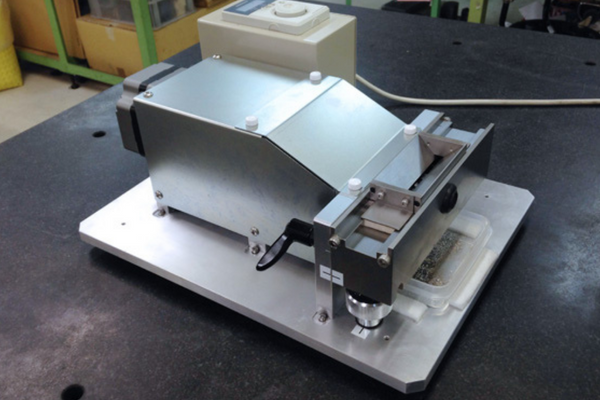

Chamfering Machine for small items

-

Beam Roatator

-

Wire EDM

-

Automated Machine

-

Design and manufacture of painting jigs and molds

-

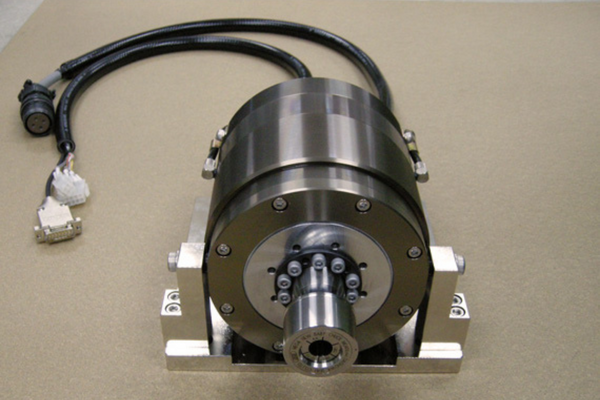

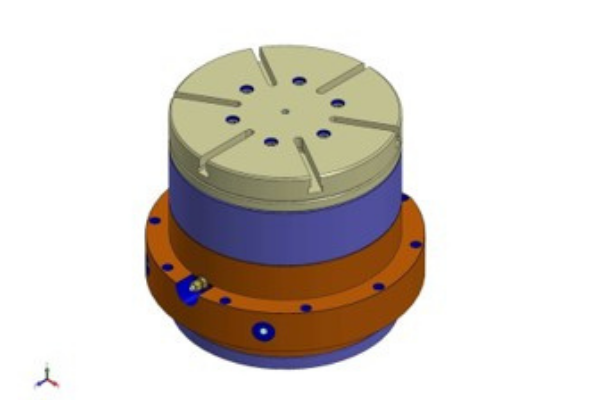

Rotary Indexing Unit

-

flange-shaft

-

Grinding ceramics